Rotational Molding Food Grade Products

While the rotational molding process is considered a 'black art' by many and generally requires a great deal of experience and expertise, providing custom rotationally molded products for food grade applications is no different. Knowledge of the proper materials such as various certified prime virgin materials that feature USDA/FDA approval for food contact, meeting or exceeding FDA standards is a must when it comes to providing custom solutions for food contact applications. If your project requires food grade materials, make sure on the front end that this is very clear to your rotational molding supplier. Granger Plastics Company has an incredible understanding of the necessities and rotational molding solutions.

Polypropylene is commonly used in rotomolding applications of food products. Polypropylene exhibits a number of physical properties that are great for food processing and manufacturing such as abrasion resistance and exposure to elevated temperatures. Some food applications require heavy wall polypropylene parts, which Granger Plastics has succeeded at, while others proclaimed that heavy wall rotational molding of polypropylene materials was virtually impossible.

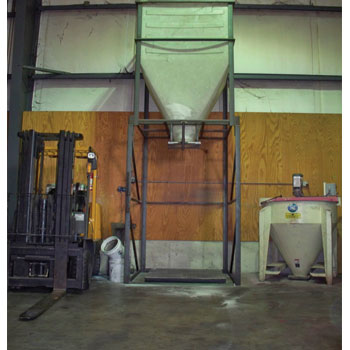

With the ability to hold tolerances much tighter than industry standards, Granger has utilized polyethylene and polypropylene in heavy wall applications to convert products and components from stainless steel to polymer based materials. Many of these material and process conversions have garnered substantial savings and process improvements for a growing number of customers.

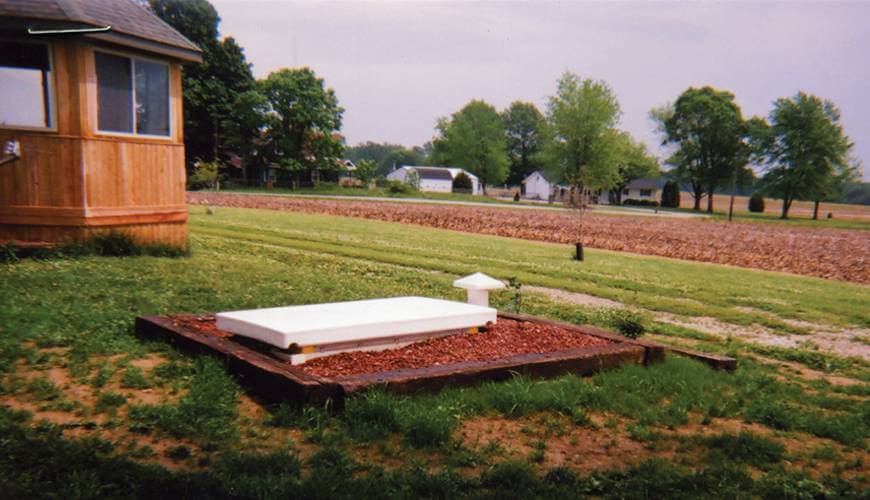

Granger Plastics Company has provided rotomolding solutions and fabricated high quality molds for rotomolding to produce food grade solutions for customers all across the country. Contact Granger Plastics Company for a free rotomolding quote of your food project conversion.